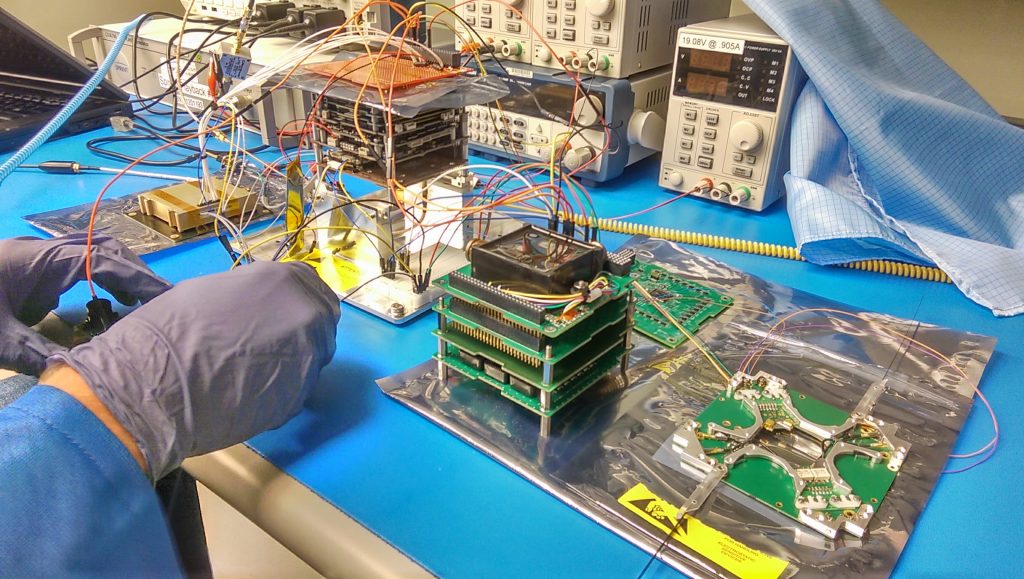

The STF-1 team has been hard at work constructing a custom mount for the camera this week. This mount will keep the camera firmly in place throughout the vibrations experienced during launch. A Computer Numeric Control (CNC) machine was utilized to cut the mount out of a solid aluminium block. The picture below displays a close-up of the machine in action!

The CNC machine takes in a special type of code, G-Code, which provides instructions for how to cut the part. This includes things like where to move, how fast to move, what path to follow, and what bit to use for the operation. G-Code is typically automatically generated from a computer model to ensure that the dimensions of the component are correct. The final product can be seen attached the the ArduCAM OV2640 Mini below. The mount will attach directly to the side of the chassis while the camera will plug into the special services card allowing it to communicate with the computer.